Ver. 8 EJ207 swapped 2002 wrx

Just finished rebuilding my motor, finally have everything running good. Just can’t get the AVCS to work.

I have CEL’s p1307 and p1309 (OCV short circuit both banks), tried clearing them, they come on 3 seconds after startup.

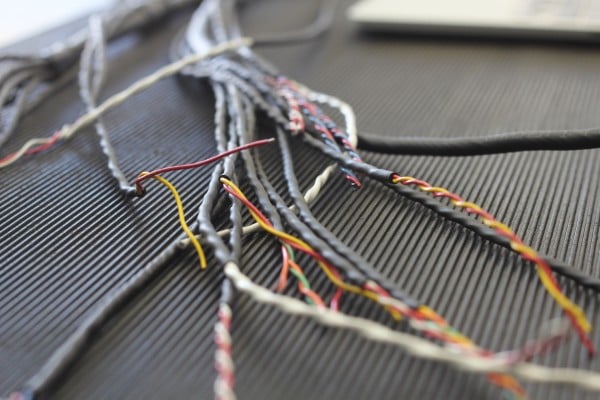

Checked all wiring/connectors, they all have continuity and everything seems to be in order, cleaned all too connections etc.

Checked/cleaned OCV, took out filters in all of the lines/banjo bolts. Tested resistance and they have ~8ohms. And put 12v to both OCV (both actuated) the entire system is as clean as can be being that I rebuilt the motor ~1500miles ago

Logged with romraider, both banks act the same. VVT angle remains at 0 (occasionally it will go to 1 or 2 when I’m letting out the clutch) duty cycle remains at 9.45%, and OCV voltage kinda jumps around all over the place

Being that CEL’s come on for both banks, I doubt it’s a mechanical issue. My best guess is maybe it has a bad ECU? It’s hard to imagine everything working except the AVCS stuff

Any ideas? I don’t have anyone to swap ECU’s with and I want to narrow it down before I go and buy a new ECU

Any help would be greatly appreciated thank you

Just finished rebuilding my motor, finally have everything running good. Just can’t get the AVCS to work.

I have CEL’s p1307 and p1309 (OCV short circuit both banks), tried clearing them, they come on 3 seconds after startup.

Checked all wiring/connectors, they all have continuity and everything seems to be in order, cleaned all too connections etc.

Checked/cleaned OCV, took out filters in all of the lines/banjo bolts. Tested resistance and they have ~8ohms. And put 12v to both OCV (both actuated) the entire system is as clean as can be being that I rebuilt the motor ~1500miles ago

Logged with romraider, both banks act the same. VVT angle remains at 0 (occasionally it will go to 1 or 2 when I’m letting out the clutch) duty cycle remains at 9.45%, and OCV voltage kinda jumps around all over the place

Being that CEL’s come on for both banks, I doubt it’s a mechanical issue. My best guess is maybe it has a bad ECU? It’s hard to imagine everything working except the AVCS stuff

Any ideas? I don’t have anyone to swap ECU’s with and I want to narrow it down before I go and buy a new ECU

Any help would be greatly appreciated thank you